1 Item(s) Added to Cart

View CartUESM96JK

New

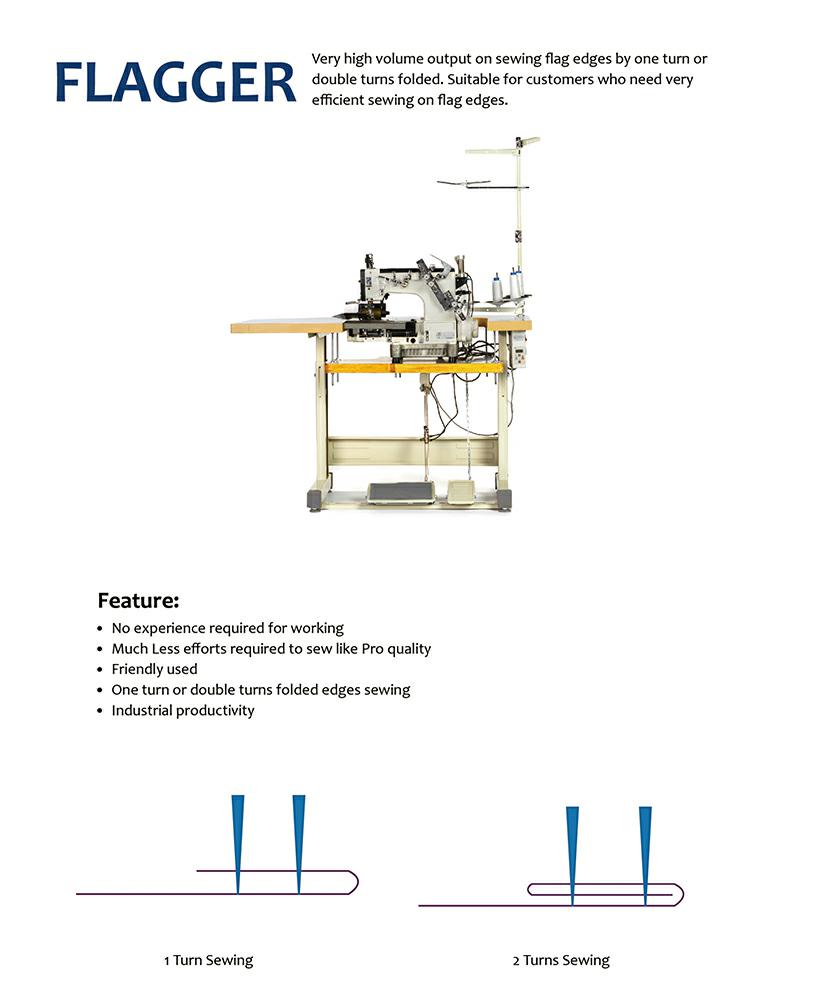

1. Very high volume output on sewing flg edges by one turn or double turns folded.

2. Suitable for customers who need very efficient industrial sewing on flag edges.

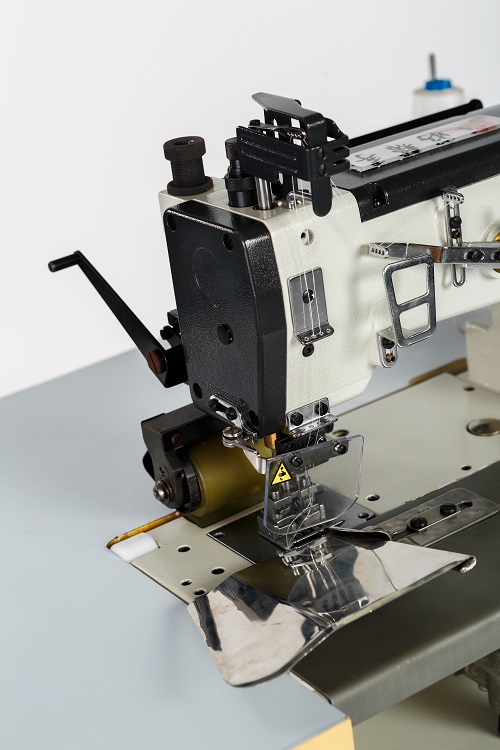

3. Fast Stitching Speed: Powerful engine, cooling system and strong needles allow the fast stitching speed to save time.

4. Strong Bulit: Whole machine has metal construction in order to have stable performance and long durability.

5. Sewing various thicknesses or intensities of textile fabrics, PVC films, tarpaulins.

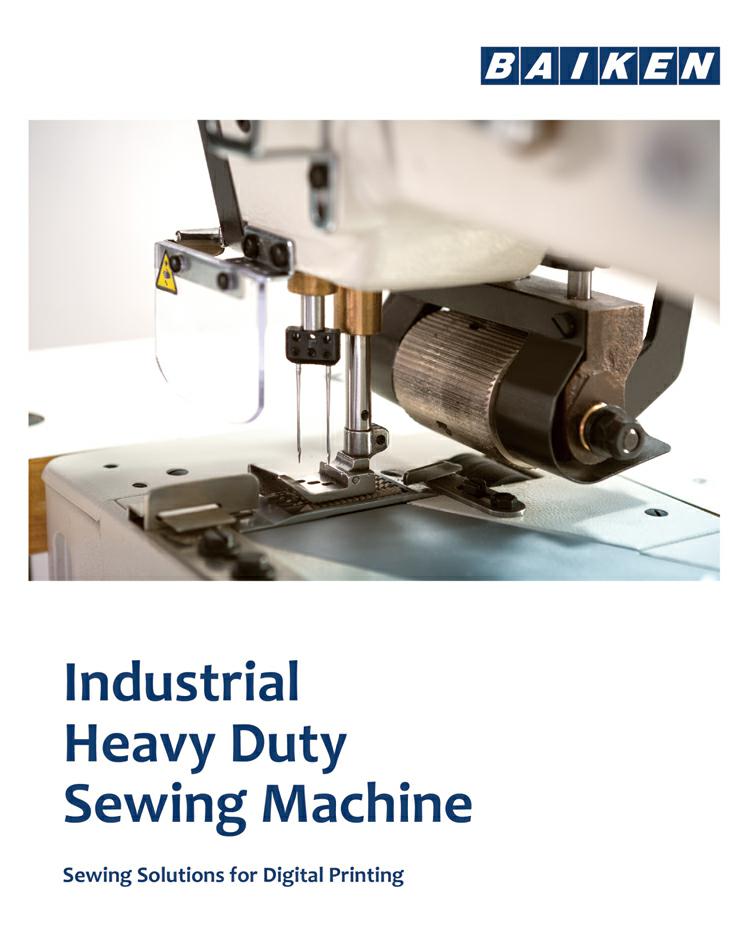

Flag hem and pocket sewing machine is specially designed for sewing the flag edges by double or single turn models. Machine operator does not need the sewing experience as this machine is used friendly.

Whole machine is strongly structured that all parts are made of metal, offering the professional sewing results and let you save time and labor by using this industrial heavy duty sewing machine.

Functions:

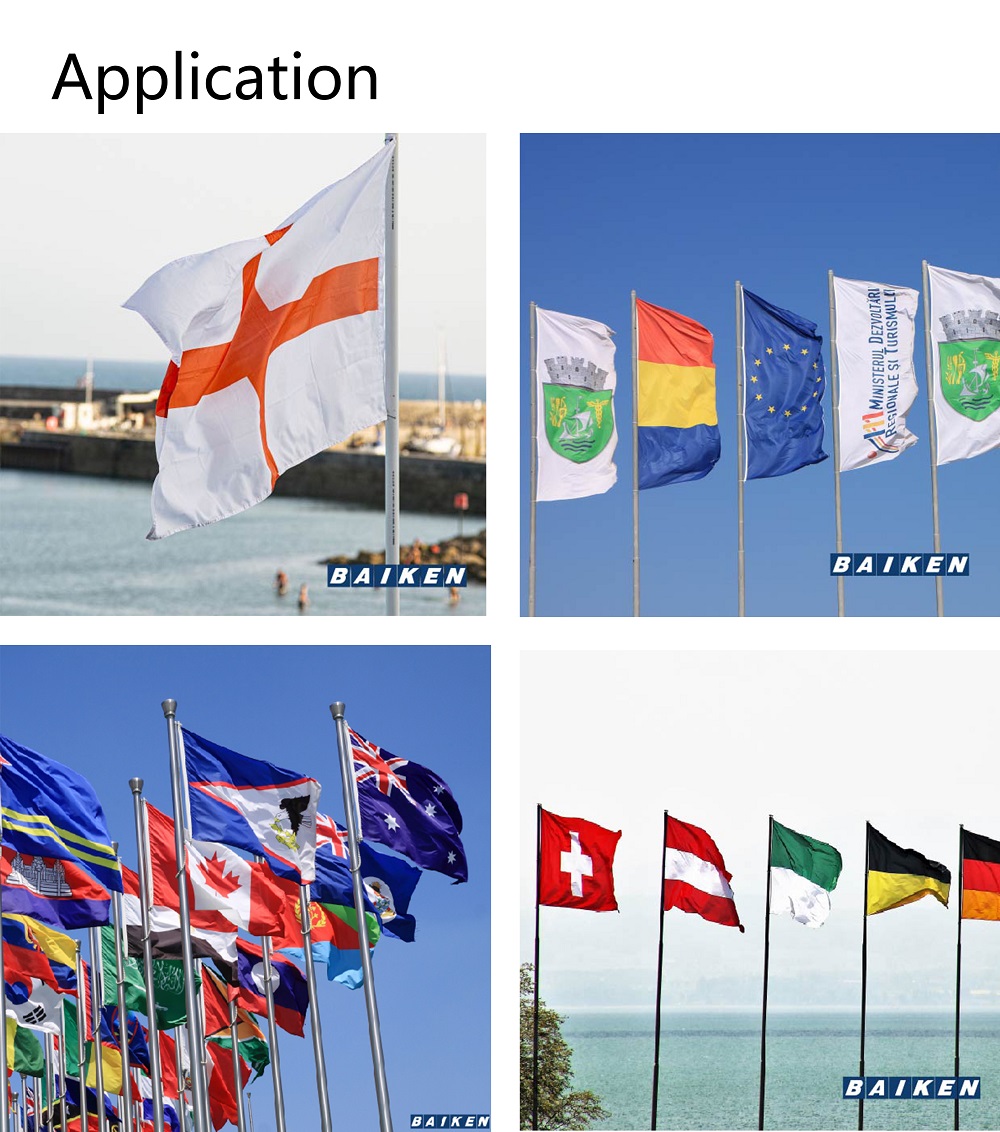

1. Suitable for big size flag sewing requirements.

2. Stable sewing performance.

3. Adjustable sewing speed as per sewing requirements.

Advantages:

1. Heavy duty sewing machine:

a. Suitable for thick and stiffen material sewing.

b. Affordable for fast stitching speed.

2. Strongly built.

a. All parts made of metal materials.

b. Strongly structured

3. Automatic working.

a. Materials feed into sewing feet automatically

b. Sewn material output automatically

4. No sewing experience required for machine operator.

a. For "starter", sewing like one professional operator.

b. Save labor cost and save sewing time.

5. LED light installed on machine to help operator watching the sewing processing clearly.

6. Adjustable sewing speed as per operator’s needs.

7. Stable performance that nearly needs no maintaining if maintain the machine on time by using our genuine accessories.

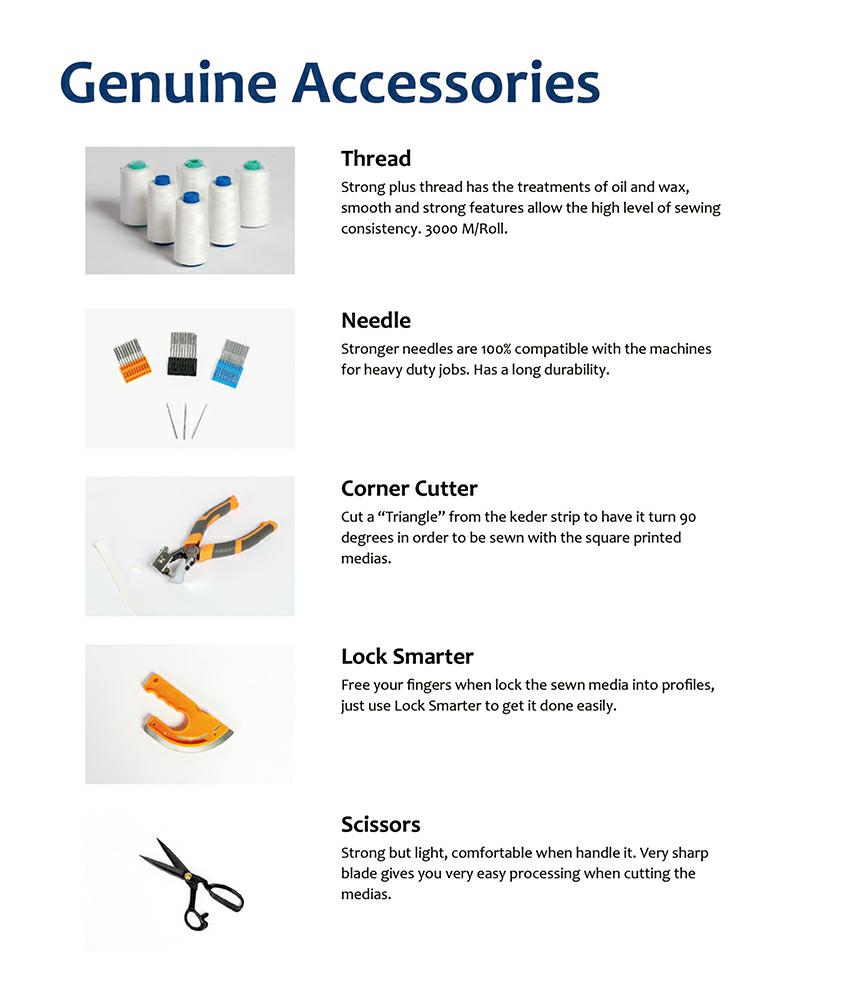

8. Supply the genuine accessories, needles, threads…

Details:

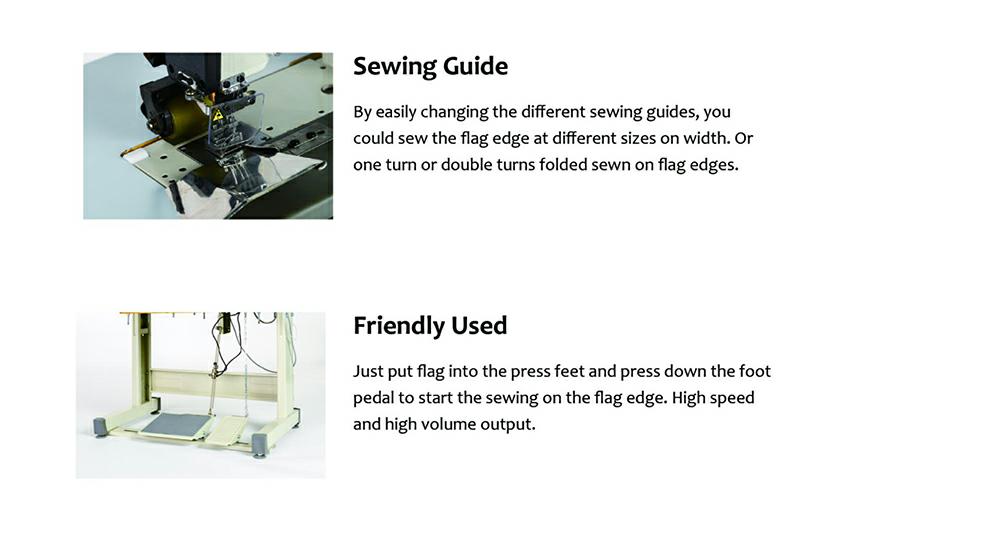

l How to put the fabric into thesewing guide tool ?

Press the right side slim feet pedal for lifting up thethreading feet on the machine so that the fabric could be inserted into thesewing guide tool.

After fabric inserted into the sewing guide tool, press theleft side foot pedal to start the sewing of the fabric.

l How to change the sewing speed ?

Our machine had been set well on the sewing speed beforeshipment. Once machine operator has more skills requiring the higher sewingspeed, press the "+" in the servo motor to increase the sewing speed

Or press"-" to down the sewing speed on request.

Application:

How to maintain the machine ?

The working room requires the very flatground for putting the machine on. The suggested working room temperature isfrom 15 to 30 degrees.

Using our original threads for more durableand continuous threading processing without stopping.

Adding the lubrication oil and cooling oilon time by checking each week.

How the flag edge pocket sewn withsingle or double turns ?

The sewing guide tool is specially designedfor both single or double turns. Customer could turn the flag into sewing guidetool as per request.

Which accessories of the machine need tobe changed ?

The needles and the threading. We stronglyrecommend our original needles and threading for the best sewing performance.

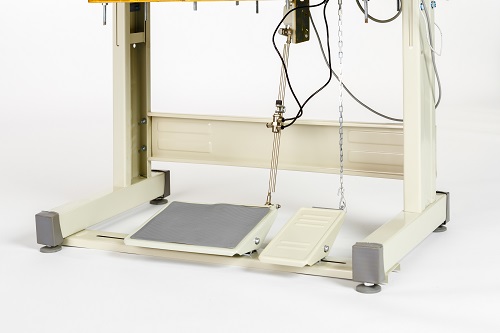

| Table size: | 24" x 47" (60 x 120cm) |

| Voltage: | 220V Single Phase 60Hz |

| Power: | 750W |

| Motor speed: | 800-3000rpm |

Flag pocket or hem model | Double or single turns |

Stitching model | Chain stitch |

| Packing size: | 52.4"x24"x35" (133x61x88cm) |

| Packing weight: | 300lbs(136kg) |